Solar Energy Systems Batteries 500-1000Kw Solar Power System With Lithium Battery For Commercial And Industrial.

Read More

Solar Energy Systems Batteries 100-500Kw Solar Power System With Lithium Battery For Commercial And Industrial Use

Read More

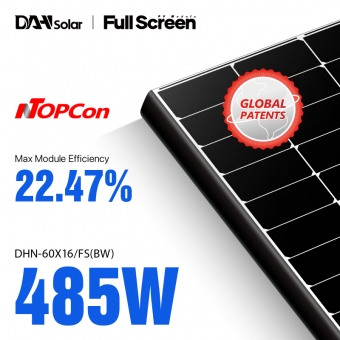

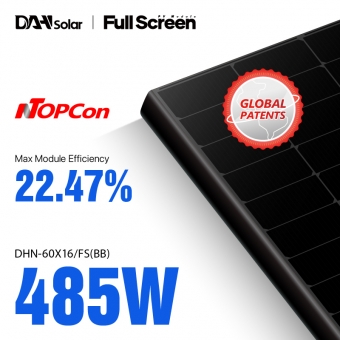

Sustainable Innovation: Full-Screen DBB PV Module Started Mass Production On 15th, May, DAH Solar announced that the Full-Screen DBB (no-bus bar) PV Module has officially started mass production, which takes half a year from design to mass production. Compared with original PV module, the Full-Screen DBB PV Module has the feature of higher efficiency and higher performance, to meet the market demand for high-performance photovoltaic modules. The product shows the ability of DAH Solar in technological innovation and industrial upgrading. The Full-Screen DBB PV Module successfully superimposed DBB technology and patented Full-Screen frameless design. The DBB technology does not have the bus bar at the position of solar cell,which can effectively improve the light receiving area. The use of smaller and more ribbons and directly connected to the fingers, which can easier to collect current and effectively reduce the power generation loss after hidden crack happened. At the same time,the original version of the Full-Screen PV Module with front frameless design can effectively increase the power generation by 6-15%. The advanced Full-Screen DBB PV Module has no bus bar and no white solder joint, the PV Module looks more tidy. The combination punch brings the PV Module performance to a higher level. DAH Solar, The Founder & Master of Frameless PV Module!

2024-05-16

26.5%! A New Record of Mass Production Conversion Efficiency of TOPCon PV Modules by DAH Solar

DAH Solar recently announced that the average mass production conversion efficiency of its TOPCon PV Modules has exceeded 26.5%, which sets a new record and continues to maintain the industry-leading level.

Compared to the theoretical limit of 28.7% efficiency, breaking through 26% surely means a lot.

The LECO laser-enhanced contact optimization technology was used to separate the two key steps of metal erosion and contact formation considering its high concentration of energy and controllability during the high-temperature sintering process, in this way the sintering process can be more precisely controlled.

The full integration of the LECO equipment was completed within 7 days, which not only improved efficiency but also effectively reduced the difficulty of Poly back, showing important significance for the long-term competitiveness of TOPCon PV Modules.

DAH Solar TOPCon base completes construction to operation in six months, achieving ramp up production in 23 days, reaching an industry-leading level in three months, and setting a new record for mass production conversion efficiency within 6 months.

As a benchmark enterprise for differentiated competition in the photovoltaic industry, DAH Solar's continuous breakthroughs and iterations in the key technology fields of the industry highlight the company's innovative strength and perseverance to industry leadership, providing a strong driving force for promoting industrial upgrading and sustainable development.

0086 137 2104 1763

0086 137 2104 1763 info@dahsolar.com

info@dahsolar.com DAHSOLAR2009

DAHSOLAR2009 +8613721041763

+8613721041763